ECONOMY/EQUITY/ECOLOGY

albert kahn's architecture of production

(n.b. this website is still in progress)

HISTORY of the Ford Motor Company

and "a theory of business"

Video courtesy of PBS American Experience documentary about Henry Ford

(aired January 29, 2013)

"I do not consider the machines which bear my name simply as machines. If that was all there was to it I would be doing something else. I take them as concrete evidence of the working out of a theory of business which I hope is something more than a theory of business - a theory that looks forward toward making this world a better place in which to live." - Henry Ford

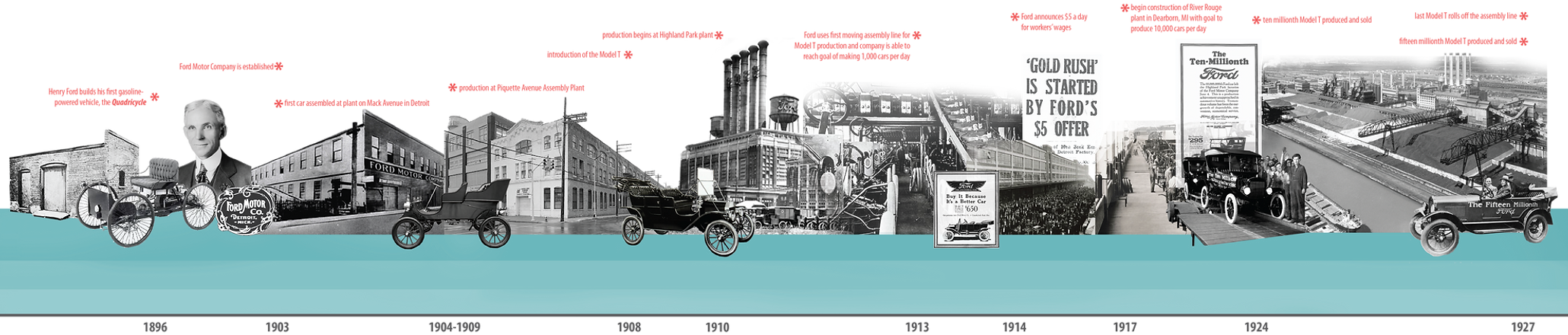

After building his first gasoline-powered vehicle, the quadricycle, in 1896 (note that Henry Ford is not responsible for inventing the automobile itself but more importantly for turning it into a successful commodity), Henry Ford finally established the Ford Motor Company on June 16, 1903, and a month later its first car was assembled at a plant on Mack Avenue in Detroit, Michigan. Shortly, production moved to the Piquette Avenue Assembly Plant until about 1909 (History.com). As Henry Ford ascended the industrial ladder, he had to tolerate much smaller and less accommodating workspaces and factories such as these and undoubtedly, the company outgrew those facilities and it was at the Highland Park Plant where Ford really began to implement his strategies of mass production with the support of Albert Kahn as his architect. Following numerous experiments starting at the beginning of the alphabet with the Model A, the Model T for which the company became famous was introduced in 1908. The demand for the Model T was incredible, and by 1913, Ford had developed revolutionary mass production methods including large production plants, the use of standardized and interchangeable parts, and most importantly the first moving assembly line. All of these methods were tested and executed at the Highland Park plant which had begun production in 1910, but when the company also outgrew that site, construction of an entirely self-sufficient 2,000 acre complex in Dearborn, Michigan called River Rouge was begun in 1917, and it was here that these methods were essentially perfected.

VISION FOR THE MODEL T

The Ford Motor Company grew out of Henry Ford's fascination with the machine and his vision for individual mobility to be experienced by all, not only exclusive to the affluent. Having felt the isolation of the farm as a child, Ford was constantly thinking of the farmer and the mechanic in designing his automobile; he wanted them to enjoy the convenience and pleasure it had to offer as well. An excerpt from the 1913 company magazine, Ford Times, sums up the objective quite well:

"I will build a motor car for the great multitude. It will be large enough for the family but small enough for the individual to run and care for. It will be constructed of the best materials, by the best men to be hired, after the simplest designs that modern engineering can devise. But it will be so low in price that no man making a good salary will be unable to own one- and enjoy with his family the blessings of hours of pleasure in God's great open spaces." (Henry Ford and Innovation, 4)

The attributes stressed most by Ford in making such a universal car, including: "quality in material to give service in use, simplicity in operation, power in sufficient quantity, absolute reliability, lightness, control, and inexpensive operation" (Mahoney), not only afforded efficiency during production, but also provided consumers with a product that they could appreciate and utilize in every-day activities. The Model T was in no way intended to be a toy for the rich, but an integral component of society.

FORD AND KAHN

At the turn of the century, most architects didn't, and didn't want to, design factories, leaving those jobs to the engineers; however it was in that very arena that Albert Kahn made a name for himself as an architect. For nearly a century, factories had been modeled after the New England textile mill, "multi-storied, framed with heavy timbers, floored with planks, and usually covered with brick" (Sherman). Kahn's innovations that incorporated the reinforced concrete constructional methods derived from his brother Julius, forever changed the factory's capacity to produce at a large scale. His structures were able to facilitate the most radical methods of manufacturing such as the assembly line even before those processes came to full fruition. His collaborations with Ford in particular favored both himself and the client, giving him the opportunity to design unbelievable structures in order to make Ford's far-fetched ambitions a reality (Bucci, 40). Kahn was the perfect candidate, always listening and prioritizing the needs of his client first. Thus, Kahn devised architectural solutions that would fulfill Ford's exacting prescriptions for lighting, cleanliness, ventilation, and the economy of interior space. He never questioned the ridiculous scale of Ford's vision and instead believed that "the designer of the building must have in mind the process of manufacture so that there may be continuous and direct flow from the receiving of the raw materials to the shipping of the finished product,...the building structure must adapt to the layout, and must not create obstacles for the movement of the piece work" (Bucci, 76). If it were not for Kahn's architectural invention, the impressive methods of the Ford Motor Company that made it so successful would have never been possible.

THE END OF AN ERA

Even the Model T had to come to an end. Henry Ford ignored the growing popularity of only slightly more expensive but more stylish and comfortable cars being produced by manufacturers such as Chevrolet, Dodge, Chrysler, and General Motors. He refused to listen to Ford executives who believed it was time for a new model. Model T sales were beginning to slip by 1923, and by the late 1920s, even Henry Ford could no longer ignore the declining sales figures. In 1927, he reluctantly shut down the Model T assembly lines and began the design of an all-new car. Just because the original design of the Model T was successful did not mean it could be successful forever, and unfortunately Ford did not realize this, only making changes in the production to reduce the cost rather than in the style, interior finishes, or new innovations like windshield wipers consumers were now demanding. The last Model T rolled off the assembly line in 1927 (Henry Ford and Innovation, 5-6).